Grades, production method, chemical composition and properties

| Grades | Production method | Nominal composition, properties |

|---|---|---|

| AP-Cu | Gas- or water-sprayed copper powder |

Cu Fe<0.2 Ni<0.04 Zn<0.05 Sn<0.05 Making products by pressing and sintering. Filler for powder compounds |

| AP-CuFe3ZnSi (Water atomization) |

Water-sprayed bronze powder for making parts |

Cu Fe3 Zn0.5 Si0.1 Good compressibility. Packed density 3.6-4.1 g/cm3 |

| AP-CuAl8.5Fe4Ni5Mn1.5 | Gas-sprayed bronze powder for coatings |

Cu Al8.5 Fe4 Ni5 Mn1.5 Anti-frictional properties, increased resistance to abrasive wear, erosive and cavitational resistance, high strength of coating adhesion against dislocation |

| AP-CuAl8.5Fe1.5Ni5Mn1.5 | Gas-sprayed bronze powder for coatings |

Cu Al8.5 Fe1.5 Ni5 Mn1.5 Anti-frictional properties, increased resistance to abrasive wear, erosive and cavitational resistance at low and high temperatures, high strength of coating adhesion against dislocation, quick coating comformability |

| AP-CuAl9 | Gas-sprayed bronze powder for coatings |

Cu Al9 Anti-frictional properties with good resistance to corrosion and good plasticity |

| AP-CuAl9Mn2 | Gas-sprayed bronze powder for coatings |

Cu Al9 Mn2 Anti-frictional properties, resistance to wear due to manganese strenghtening, and high resistance to corrosion |

| AP-CuSi3Mn1 | Gas-sprayed bronze powder for coatings |

Cu Si3 Mn1.3 Anti-friction properties, resistance to corrosion in salt- and fresh-water, good workability, and increased elastic properties |

| AP-CuPb30 | Gas-sprayed bronze powder for coatings |

Cu Pb30 High anti-friction properties during operation under increased pressure and high slip speeds, and high heat conductivity |

| AP-CuAl9.5Fe1 | Gas-sprayed bronze powder for coatings |

Cu Al9.5 Fe1 Anti-friction properties with good resistance to corrosion and increased mechanical properties |

| AP-CuSn4 AP-CuSn10 AP-CuSn20 (Water atomization) |

Water-sprayed bronze powders for making parts using the PM method |

Cu Sn4 Cu Sn10 CuSn20 Good compressibility. Particle size: base fraction 0-160 microns. Packed density 3.5-4.5 g/cm3 |

| AP-CuSn15 | Water-sprayed bronze powders for making parts using the PM method |

Cu Sn15 Base fraction – less than 40 microns. Packed density ≥ 3.8 g/cm3 |

| AP-CuSn8P0.3 | Gas-sprayed bronze powder for coatings |

Cu Sn8 P0.3 Anti-friction properties, increased hardness, durability, wear-resistance and corrosion-resistance, improved workability |

| AP-CuSn10P1 | Gas-sprayed bronze powder for coatings |

Cu Sn10 P1 Excellent anti-friction and elasticity properties, increased hardness, wear- and corrosion-resistance, improved workability, good sintering behavior during filters manufacturing using the PM method |

| AP-CuSn5Zn5Pb5 | Gas-sprayed bronze powder for coatings |

Cu Sn5 Zn5 Pb5 Good anti-friction properties, improved technological properties (workability), resistance to corrosion. Anti-scuffing, dense coatings on pipe threaded joints |

| AP-CuSn5Zn5Pb5 AP-CuSn4Zn8Pb5 (Water atomization) |

Water-sprayed bronze powders for making parts using the PM method |

Cu Sn5 Zn5 Pb5 Cu Sn4 Zn8 Pb5 Compressed powder for making friction bearings and thermal compensators. Particle size: 0-160 microns, packed density 3.6-3.9 g/cm3, compactibility >7.9 g/cm3 at a pressure of 600 MPa. |

| AP-CuSn7Pb10 | Gas-sprayed bronze powder for coatings |

Cu Sn7 Pb10 Zn1 P<0.5 Fe<0.5 Anti-friction and improved technological properties in coatings on sleeves (friction bearings) oil-seal rings. Resistance to cavitation |

| AP-CuSn10Pb10 | Gas-sprayed bronze powder for coatings |

Cu Sn10 Pb10 High anti-friction and corrosion-resistance properties at high pressure and high slip speeds |

| AP-CuSn10Pb1.5 | Gas-sprayed bronze powder for coatings |

Cu Sn10 Pb1.5 Anti-friction properties, resistance to corrosion, wear-resistance at high pressures |

| AP-CuSn4Zn4Pb17 | Gas-sprayed bronze powder for coatings |

Cu Sn4 Zn4 Pb17 High anti-friction properties, resistance to corrosion in deposited coatings, good workability |

| AP-CuSn8.5Ni3 | Gas-sprayed bronze powder for coatings |

Cu Sn8.5 Ni3 Si1 Anti-frictional, corrosion-resistant and wear-resistant properties, good adaptability in sliding couplers, and good coating adhesion against dislocation; low coating oil-absorption |

| AP-CuSn8Ni5Si1B1 | Gas-sprayed bronze powder for coatings | Cu Sn8 Ni Si BSelf-fluxing properties. Wear-resistant friction coatings on parts made from copper alloys, steel and cast iron, HRB140-160 |

| AP-CuCr1 | Gas-sprayed bronze powder for coatings |

Cu Cr1 Wear-resistance combined with high electrical and heat conductivity and heat-resistance |

| AP-FeCu30 (Water atomization) |

Water-sprayed copper-based pseudo-alloy powder |

Fe Cu30 Compressed powder for making construction parts and composites using the PM method. Dampening properties and corrosion resistance |

| AP-Cu63Zn37 AP-Cu70Zn30 AP-Cu80Zn20 AP-Cu90Zn10 (Water atomization) |

Water-sprayed bronze powders for making parts using the PM pethod |

Cu Zn37 0-100 microns, 0-200 microns and other Cu Zn30 0-280 microns, packed density 3-3.5 g/cm3 Cu Zn21 0-280 microns, packed density 3.2-3.6 g/cm3 Cu Zn10 0-280 microns, packed density 3.05-3.55 g/cm3. Fluidity <35 s |

| AP-Cu63Zn37 | Gas-sprayed brass powder for coatings |

Cu Zn37 High durability and wear-resistance in coatings |

| Grade | Brazing temp, °C | Weld strength, MPa | Field of application |

|---|---|---|---|

| AP-CuMn32Ni8Si3 (PAN-3) |

1000 | 300-350 | Brazing with flux agents 200 or 201, 209 carbonic and alloyed structural steels and cast iron |

| AP-CuMn25SiNiB (PAN-9) |

900 | 250-300 | Brazing with flux agent 209 for steels, and flux agent FPSN-2 for cast iron |

| AP-CuMn24Ni5 (VPr-2) |

1000-1040 | 280-360 | Brazing alloy with increased heat-resistance and resistance to corrosion. Brazing of heat exchange units made from heat- and corrosion-resistant steels and alloys |

| AP-CuMn29Ni29Co5SiB (VPr-2) |

1000-1050 | 350 | Brazing of thin-walled structures and stainless steels (12Cr18Ni10Ti steel) and alloys. Increased corrosion resistance |

| AP-Ni58B AP-Ni58V |

1080-1100 | 400-470 | Vacuum brazing of high-strength stainless steels and nickel alloys and thin-wall structures |

| AP-NiMn18CrMoCu (VPr-33) |

1120 | σcp 220 | Argon or vacuum brazing of stainless steels and heat-resistant alloys operating at high temperatures |

| AP-NiMn34Co10 (VPr-7) |

1160 | 450-520 | Argon or vacuum brazing of thin-walled structures made of stainless steels and heat-resistant alloys |

| AP-FeMn32Ni12Cu12SiB (P-87) |

1200 | 350-400 | Brazing of pipes joints in steel gas main pipelines |

| P-Cr13Ni69Si7B (No 5N) |

1200 | 280-300 | Argon brazing of corrosion-resistant and heat-resistant steels. Joint strength at 800 °C is 200 MPa |

| P-Cr10Ni64Mo15Si7B (6MA) |

1200 | 320-340 | Argon brazing of corrosion-resistant and heat-resistant steels. Unbrazing temperature is 1230 °C |

| P-CuSn5P7 P-CuSn5P7-P |

700-720 | 180-200 | Brazing of copper and copper alloys with the brazing agent PV-209. Substitute for high-silver brazing alloys PSr25, PSr45. P-CuSn5P7-P is an extrudable modification of this brazing alloy |

| P-NiMn18CrMoCu (VPr-33) |

960-970 | σcp 400 | Brazing of titanium and titanium alloys. Temperature of extended operation is 400 °C |

| P-Ti44Zr24Cu16Ni16 (VPr-28) |

880-980 | σcp 400 | Brazing of titanium and titanium alloys. Temperature of extended operation is 400 °C |

| P-Fe60NiCrB | 1185 | σcp 400 | Brazing of a compound tool made from rapid machining steel in molten BaCl2 salt while tempering a cutting edge |

| P-Cu53Zn21MnNi (P100) |

950-1000 | 260-300 | Brazing with brazing agents F-1, PV200 of hard alloys of the type W-Co with steel |

| P-Cu76Sn9Zn9Ni (P102) |

940-960 | 260-300 | Brazing of brittle grades of hard alloys |

| P-Cu63Zn (PAN-212) |

1015 | - | A mixture of a brazing alloy with a brazing agent. Brazing of tools made from hard alloys of the types W-Co, Ti-W-Co |

| P-NiCr9FeSiB (VPr11-40N) |

1100-1120 | - | Self-fluxing structural brazing agent for brazing corrosion-resistant steels and alloys in motor-building, and vacuum or argon brazing of segments of turbine blades |

Powder grades, nominal chemical composition and properties of coatings

| Grades | Nominal composition | Coating Hardness, HRC | Properties |

|---|---|---|---|

| PG-S27 | Fe C3.9 Cr26 Si 1.5 Ni1.7 W 0.3 Mo0.1 Mn1.1 | ≥ 54.2 | Resistance to abrasive wear at restrained load impacts and temperature max. 500 0C |

| PG-S1 | Fe C2.9 Cr29 Si3.5 Mn1 Ni4 | ≥ 54 | Resistance to abrasive and gas-abrasive wear |

| PG-US25 | Fe C4.9 Cr38 Si2.1 Ni1.4 Mn ≤ 2.5 | ≥ 55.9 | Resistance to intensive abrasive wear without impacts |

| PG-FBH6-2 | Fe C4.5 Cr34 Si1.7 Mn2.7 B1.6 | ≥ 53.2 | Resistance to abrasive wear (deposition onto the equipment of coal-mining industry) |

| PG-AN1 | Fe C2.4 Cr29 Si2 Mn1 B1.5 | ≥ 54 | Resistance to abrasive wear at restrained load impacts (protective coatings for metallurgic equipment, agricultural technique, construction machinery etc.) |

| AP-FeCr30SiBNiCuAl | Fe C4.9 Cr30 Si3.2 Ni1.4 Mn1 B2 Cu0.6 Al0.4 | ≥ 60 | Deposition of abrasive-resistant coatings onto the working components of agricultural machinery etc. |

| AP-FeCr18VNiMo (PN-AN2) | Fe C Cr V Ni Mo Me | 42-43, 51-53 at 650 0C | Resistance to abrasive wear, tear and corrosion (protective coatings of polymers’ augers) |

| AP-FeNi15Cu7 | Fe C2.6 Ni15 Cu7 Cr2.2 Si2.2 Mn1 | 240-200 HB | Restoration of iron casting faults |

| AP-FeNiCr14Mo5WSiB | Fe C1.4 Ni37 Cr14 Mo5 W4 Si2.5 B2.2 | >35 | Resistance to mechanical wear and corrosion, self-fluxing properties |

| Nominal chemical composition, % | |||||

|---|---|---|---|---|---|

| Grade | Co | Cr | Ni | Fe | Admixtures |

| AP-CoCr23Ni26 | 25,00-28,00 | 22,00-24,00 | 25,00-27,00 | Bal. | - |

| AP-CrNi24Co24Al | 23,00-26,00 | 20,00-24,00 | 21,00-25,00 | Bal. | Al, Mn |

| AP-CrNi23Co23Al | 20,00-24,00 | 20,00-24,00 | 20,00-24,00 | Bal. | Al, Mn |

| AP-CrNi18Co18Cu20Al | 16,00-20,00 | 16,00-20,00 | 15,00-19,00 | Bal. | Cu, Al, Mn |

| AP-CrNi21Co21Mn20 | 19,00-22,00 | 17,00-21,00 | 19,00-22,00 | Bal. | Mn 17,00-22,00 |

| AP-CrNi20Co20Cu21 | 18,00-22,00 | 16,00-20,00 | 19,00-22,00 | Bal. | Cu, Mn |

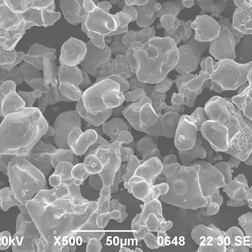

Photo of AP-CoCr23Ni26 particles, grain size 20-56 mkm.

| Power grade | Nominal chemical composition, % | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Main components | Maximum admixtures | |||||||||||

| Fe | C | Cr | W | Mo | V | Co | Si | Mn | Ni | S | O | |

| AP-FeW6Mo5 | base | 1 | 4 | 6.5 | 5 | 2 | - | <0.5 | 0.55 | 0.4 | 0.03 | 0.03 |

| AP-FeW6Mo5-shot blasting | base | 1 | 4 | 6.5 | 5 | 2 | - | <0.6 | 0.65 | 2 | 0.03 | n/a |

| AP-FeW0Mo6V1 | base | 0.75 | 4 | - | 6 | 1 | - | <0.4 | 0.55 | 0.4 | 0.03 | 0.03 |

| AP-FeW0Mo6V1Co8 | base | 0.75 | 4 | - | 6 | 1 | 8 | <0.4 | 0.55 | 0.4 | 0.03 | 0.03 |

| AP-FeW0Mo6V3Co8 | base | 1.2 | 4 | - | 6 | 2.5 | 8 | <0.4 | 0.55 | 0.4 | 0.03 | 0.03 |

| AP-FeW0Mo2V3Si | base | 1.2 | 4 | <0.8 | 2.5 | 3 | <0.5 | 0.5 | 0.55 | 0.35 | 0.03 | 0.03 |

| AP-FeCr5W3MoV5Si2 | base | 1.7 | 5.5 | 3 | 0.5 | 5 | - | 2 | 0.8 | 0.4 | 0.03 | 0.03 |

| AP-FeCr6WMoV8Si | base | 2.1 | 6 | 1 | 0.5 | 8 | - | 1 | 1 | 0.4 | 0.03 | 0.03 |

| AP-FeCr3WMoV5Si | base | 1.3 | 3 | 1.5 | 1.5 | 5 | - | 0.8 | 0.5 | 0.4 | 0.03 | 0.03 |

| AP-FeCr12MoV | base | 1.5 | 12 | - | 0.5 | 0.3 | - | - | 0.4 | 0.4 | 0.03 | 0.03 |

| AP-FeCr12MoV3Ti | base | 2.2 | 12 | - | 0.5 | 3 | Ti 0.08 | - | 0.6 | 0.4 | 0.03 | 0.03 |

| AP-FeCr18MoVCo2 | base | 1 | 18 | <0.3 | 1.2 | 0.15 | 1.5 | <1 | 1 | 0.45 | 0.03 | 0.05 |

| AP-FeCr8W2V2Co | base | 0.9 | 4.5 | 2.5 | - | 2 | - | 1.4 | 1 | n/a | n/a | n/a |

AP – Atomized Powder

High Steel Powders:

AP-FeW6Mo5, AP-FeMo6V1, AP-FeMo6V1Co8, AP-FeMo6V3Co8, AP-FeMo2V3Si. AP-FeW6Mo5-b is for bead-blasting treatment, microhardness is ≥400 HV 0.05 /5 (acc. to specification); 750-1000 HV (factual).

Die Steel Powders:

AP-FeCr5W3MoV5Si2, AP-FeCr6WMoV8Si, AP-FeCr3WMoV5Si, AP-FeCr12MoV, AP-FeCr12MoV3Ti AP-FeCr18MoVCo2, AP-FeCr8W2V2Co

Chemical composition

| Grade | Nominal composition, % | |||||||

|---|---|---|---|---|---|---|---|---|

| Co | Cr | W | Ni | Si | B | C | Fe | |

| AP-CoCr30Ni6WSiB (AN34) | base | 30 | 4.5 | 6 | 2 | 0.8 | 0.8 | ≤3 |

| AP-CoCr30Ni2WSi (AN35) | base | 30 | 4.5 | 2 | 2 | - | 1.5 | ≤3 |

| AP-CoCr30WSi (V3K) | base | 30 | 4.5 | 1.2 | 2.5 | ≤0.1 | 1.1 | ≤2 |

| AP-CoCr26W14Si (3V16K) | base | 26 | 14 | ≤3 | 0.75 | - | 3.2 | ≤5 |

| AP-CoCr33W18Si | base | 33 | 17.5 | ≤3 | 1.5 | - | 2.3 | ≤5 |

Powder grades and properties

| Name, grade, base grains | Nominal composition % | ||||||

|---|---|---|---|---|---|---|---|

| Fe | Cr | Ni | Si | Mo | Al | Other | |

| Ni Al5 powder AP-NiAl5 alloy gas-sprayed -40, 11-53, 40-100, 40-125, 45-106 microns | ≤1.0 | - | base | - | - | 5 | C≤0.05 Si, Fe, Mn≤1 each |

| Stainless steel powder AP-FeCr18Ni9gas-sprayed -40, 20-63, 40-100, 90-160 microns | base | 18 | 9 | - | - | - | C ≤0.12 |

|

Stainless steel powder RP-FeCr18Ni9Ti reduced -56 packed density 2.2-3.0 g/cm3 -160 packed density 2.0-2.6 g/cm3 -280 packed density 1.7-2.6 g/cm3 |

base | 18 | 9 | - | - | - | C0.08 Ti0.8 O≤0.35 S≤0.02 Ca≤0.15 |

|

Stainless steel powder RP-FeCr18Ni15 reduced -56 packed density 1.9-2.5 g/cm3 -160packed density 1.8-2.5 (3.0) g/cm3 -280 packed density 1.7-2.5 g/cm3 |

base | 18 | 15 | - | - | - | C≤0.08 O≤0.30 S≤0.015 Ca≤0.15 |

|

Stainless steel powder RP-FeCr17Ni2 reduced -56 packed density 2.2-3.0 g/cm3 -160 packed density 2.0-2.6 g/cm3 -280 packed density 1.7-2.6 g/cm3 |

base | 17 | 2 | - | - | - | O≤0.35 S≤0.02 Ca≤0.20 C0.12 |

|

Stainless steel powder RP-FeCr23Ni18 reduced -56 packed density 2.2-3.0 g/cm3 -160 packed density 2.0-2.6 g/cm3 -280 packed density 1.7-2.6 g/cm3 |

base | 23 | 18 | - | - | - | C≤0.08 O≤0.30 S≤0.02 Ca≤0.15 |

|

Stainless steel powder RP-FeCr13Mo2 reduced -160packed density 2.1-2.45 g/cm3 -280 packed density 2.0-2.6 g/cm3 |

base | 13 | - | - | 2 | - | C≤0.08 O≤0.50 S≤0.02 Ca≤0.20 |

|

Nichrome powder Ni80Cr20 AP-Cr20Ni80 (Nitrogen atomization) AP-Cr20Ni80 (Water atomization) -40, 20-63, 40-100, 80-160 microns |

≤1.0 | 20.5 | base | - | - | - | Si≤0.5 O≤0.05 Mn≤0.1 each |

|

Nichrome powder Ni80Cr20 RP-Cr20Ni80 reduced -160 packed density 2.0-2.6 g/cm3 -280 packed density 1.7-2.6 g/cm3 |

- | 20 | base | - | - | - | C≤0.06 O≤0.30 S≤0.01 Ca≤0.20 |

|

Nichrome powder Ni60Cr40 RP-Cr40Ni60reduced |

- | 40 | base | - | - | - | C≤0.06 S≤0.02 Ca≤0.20 |

|

Powder of FeCr30 alloy RP-FeCr30reduced -56 packed density 2.2-3.0 g/cm3 -160 packed density 2.0-2.6 g/cm3 -280 packed density 1.7-2.6 g/cm3 |

base | 30 | ≤0.30 | - | - | - | C≤0.30 O≤0.30 S≤0.01 Ca≤0.20 |

|

Stainless steel powder AP-FeCr17Ni12Mo3 gas-sprayed 11-53, 45-106 microns |

base | 17 | 12 | - | 2.5 | <0.6 | Mn≤0.8 C≤0.1 |

|

Stainless steel powder AP-FeCr19Ni9Si5Mo4NV gas-sprayed 80-200 microns |

base | 19 | 9 | - | 4.5 | - | N, Si, Mn, V C≤0,08 |

|

Stainless steel powder AP-FeCr19Ni11Mo2 gas-sprayed -40, 40-100, 80-400, 100-280 microns |

base | 19 | 11 | - | 2.5 | - | C≤0.08 O≤0.05 Mn1.5 |

|

Stainless steel powder AP-FeCr20Ni2 gas-sprayed -40, 20-63, 40-100, 80-200 microns |

base | 13 | 2.2 | - | - | - | Mn0.8 C0.2 |

|

Stainless steel powder AP-FeCr13 gas-sprayed -40, 20-63, 40-100, 80-200 microns |

base | 13 | - | - | - | - | C0.3 Ni≤0.6 Si≤0.8 Mn≤0.8 Ti≤0.2 Cu≤0.3 S≤0.025 P≤0.03 |

|

Stainless steel powder AP-FeCr18Ni9MoCuSi water-sprayed 630-2000, 630-2500 microns |

base | 18 | 9.5 | 0.8 | 0.9 | - | Cu0.9 C≤0.12 O≤ 0.45 |

Powders developed for special application:

| Name, grade, base grains | Nominal composition % | ||||||

|---|---|---|---|---|---|---|---|

| Fe | Cr | Ni | Si | Mo | Al | Other | |

| AP-FeCr17Ni8Si6Mn (ZN-6L)gas-sprayed powders 63-125 microns | base | 17 | 8 | 6 | - | - | C0.08 Mn1 Co≤0.2 S≤0.025 P≤0.03 O≤0.08 N≤0.09 |

| AP-FeCr18Ni9Mo5Si5Mn4Nb (ZN-12M) gas-sprayed powders 63-125 microns | base | 18 | 9 | 5 | 5 | - | C0.10 Mn4 Nb1 Co≤0.2 S≤0.025 P≤0.03 O≤0.08 N≤0.09 |

| Grade | Nominal Composition | Use |

|---|---|---|

| AP-FeNi4Cu2Mo | Fe C≤0.12 Ni4 Cu1.5 Mo0.5 | A component of powder mixtures for depositing wear-resistant coatings using plasma spraying and welding deposition |

| AP-FeCr25Mn13Ni3 | Fe C0.5 Si0.5 Cr25 Mn13 Ni3 | Wear-resistant coatings deposited by plasma spraying. Increased viscosity and wear-resistance for friction with pressure and shocks |

| AP-X5 | Fe base | Hardness of 58-62 HRC. High wear-resistance under shocks and slip velocity and in aggressive environments |

| AP-N10 | Fe base | Hardness of 40-46 HRC. High wear-resistance under heavy loads and slip velocity and in aggressive environments. Resistant to cavitation |

| AP-N4 | Fe base | Hardness of 48-52 HRC. High wear-resistance under heavy loads and slip velocity and in aggressive environments |

| Powder Grade | Composition, % | Hardness, HB, typical values | Adhesion strength, MPa, min |

|---|---|---|---|

| CP-Al5-Ni | Ni+5.2AI | 210 | 55 |

| CP-Al10-Ni | Ni+9AI | 170 | 55 |

| CP-Al-NiCr15SiB2 | NiCr15Si3B2+1.2AI | 360 | 55 |

| CP-Al-NiCr16SiB3 | NiCr16Si3B3+1.2AI | 380 | 55 |

CP - conglomerated powder

Particle size 40 - 100 mkm.

| Powder grade Particle shape Base grain |

Nominal chemical composition, % | ||||||

|---|---|---|---|---|---|---|---|

| Basic components and admixtures | |||||||

| Fe | Cr | Ni | Co | Mo | Al | Other | |

|

AP-NiAl5 gas-sprayed, spheroidal -40, 11-53, 40-100, 40-125, 45-106 |

<1.0 | - | base | - | - | 5 | С <0,1, Si, Fe, Mn <1 |

|

AP-Cr20Ni80(Nitrogen atomization) gas-sprayed,

spheroidal AP-Cr20Ni80(Water atomization) water-sprayed, round -40, 20-63, 40-100, 80-160 microns |

<1.0 | 20.5 | base | - | - | - | C, Mn <0.1 each Si <0.5 O<0.05 |

|

RP-Cr20Ni80reduced, irregular fr. -40, 40-100, 40-160 microns |

<0.3 | 20 | base | - | - | - | C <0.06 S <0.01 Si<0.1 O<0.3 |

|

RP-FeCr25Al6reduced, irregular -45, -63, -280 microns |

base | 25 | -- | -- | -- | 6 | C <0.2 each |

|

RP-FeCr20Al6Yreduced, irregular -45, -63, -280 microns |

base | 20 | - | - | - | 6 | C <0.2 Y |

|

RP-FeCr25Al10reduced, irregular -45, -63, -280 microns |

base | 25 | - | - | - | 10 | C <0.2 |

|

RP-Ni70Al30reduced, irregular 20-63 microns |

<0.2 | - | base | - | - | 30.5 | C <0.07 |

|

RP-Ni85Al15reduced, irregular 20-63, 40-100 microns |

<0.2 | - | base | - | - | 15 | C <0.07 |

|

RP-Ni55Ti45reduced, irregular 20-63, 40-100 microns |

<0.2 | - | base | - | - | - | Ti 45 C <0.07 |

| RP-Ni75Al23W (VKNA)reduced, irregular -56 microns | <0.2 | + | base | + | + | 23 | chem. comp. by request |

|

RP-NiCr20Al10reduced, irregular -45, -63, -280 microns |

- | 20 | base | - | - | 10 | C <0.2 |

|

RP-NiCr16Al6Yreduced, irregular -45, -63, -280 microns |

- | 16 | base | - | - | 6 | Y 0.5 Ca, C <0.2 each |

|

RP-NiCr20Co20Al13reduced, irregular -40,-63, 40-100 microns |

<0.3 | 20 | base | 20 | - | 13 | Y Si Nb C 0.01-0.15 |

|

AP-NiCr22Al10Y * gas-sprayed, spheroidal (analog Amdry 962 / NiCrAlY 66 22 10 1) |

- | 21,00-23,00 | base | - | - | 9,00-11,00 | Y 0,80-1,20 S+P+Si+Mn max 1,00 % |

|

AP-CrNi67Al12* gas-sprayed, spheroidal (analog Amperit 457.642) |

- | 19,00-21,00 | base | - | - | 11,00-12,00 | Y 0,20-0,50 Re 0,70-0,90 Hf 0,70-0,90 |

|

RP-NiCr20Sireduced, irregular -40,-63, 40-100 microns |

- | 20 | base | - | - | - | Si 2 |

*New materials: Ni-Cr-Al-Y system alloys for coatings application in aerospace industry.

Alloys of the Ni-Cr-Al-Y system are most widely used to obtain coatings on blades operating at high temperatures and thermal stresses.

Sprayed powders may be delivered with other particle size not presented in the table, in microns: 45-125, -125, 100-140, 100-280, 160-280, 280-400.

Properties of NiAl metallides

Erosion-resistant alloyed powders AP-FeCr17Ni8Si6Mn (ZN-6L) and AP-FeCr18Ni9Mo5Si5Mn4Nb (ZN-12M) were developed for high-performance and high-quality plasma-jet hard-facing of wear-resistant coatings onto sealing surfaces of power equipment valving parts in lieu of the coating electrodes well-known in the valving industry. Powder grades designation in brackets are the grades of coating electrodes according to GOST 100The basic phase in the material RP-Ni70Al30 is the metallide NiAl (β` - phase >95%), while in RP-Ni85Al15 it is the metallide Ni3Al (γ`- phase >95%), and in VKNA the metallide Ni3Al (γ`- phase). The materials' structure in a coating is marked by high resistance to recrystallization during use at high temperatures.

Particle shape

Particle size

Base fraction 20-63 microns, VKNA powder 56 microns.

The typical average size (conditional diameter) of powder particles is 30-40 microns.

Physical-mechanical properties of powders and coatings

VKNA is a heat-resistant super-alloy based on the metallide Ni3Al, phase-strengthened with admixtures of infusible metals, which is characterized by outstanding physical and mechanical properties of plasma coatings: structural thermal stability, heat-resistance and wear-resistance when used as parts in gas-turbine engines at temperatures of 1150-1200 0C.

RP-Ni70Al30 Smelting temperature 1640 0C. Exclusively high heat-resistance when heated in open air, more than three times greater resistance to corrosion than the common heat-resistant alloy CrNi77TiAlB.

| Material | C over a period of 100 hrs | ||

|---|---|---|---|

| 1000 | 1100 | 1200 | |

| RP-Ni70Al30 | 0.06 | 0.1 | 0.2 |

| CrNi77TiAlB (NiCr20Ti2,5Al) | 0.14 | 0.36 | 0.65 |

RP-Ni70Al30 in plasma coatings is corrosion-resistant in the atmosphere, water and in alkalis (NaOH and KOH solutions).

Surface hardness is approximately 40 HRC; the material forms durable coatings with steel and copper and is well pressed and sintered in a vacuum.

RP-Ni85Al15 Melting point is 1400 0C; excellent heat-resistance of coatings when heated in open air to 1150 0C; the material and coatings are durable in the atmosphere, water and alkalis.

Hardness of plasma coatings is approximately 300 HB; the material forms durable coatings with steel and copper.

Use

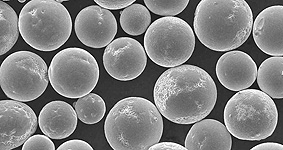

Powders of magnetically soft nickel-based alloys doped with molybdenum are super permalloys that are characterized by extremely high magnetic permeability. Light magnetization of alloys in weak fields is marked by the near-absence of magnetic anisotropism and magnetostriction effects. Molybdenum boosts the unit-area resistance and the initial magnetic permeability of permalloys and decreases their vulnerability to mechanical deformations. By applying high-purity constituents and showing special attention to thermal processing, super permalloys achieve the highest magnetic permeability among common magnetically soft materials.

Spheres of application: PM production of magnetic elements – core rods with high magnetic permeability used to equip measurement and radiotechnical devices.

Spherical molybdenum permalloy powder, sprayed with an inert gas, and with a base grain size of -100 microns (less than 100 microns) without additional sieving or sintering is used, for example, in obtaining compositional magnetic material with dielectrical isolation. In this case, powders with added insulation and plasticiser are pressed in hard matrices at high pressure; then, the semi-finished products are sintered in a vacuum or a protective atmosphere.

| Grade | Nominal composition, % | Admixtures, %, maximum | Packed density g/cm3 | Plasticity, с/50g | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Ni | Mo | Mn | Fe | C | Si | S | O | |||

| AP-Ni81Mo3Fe | 81 | 2.7 | 0.9 | Res. | 0.05 | 0.1 | 0.02 | 0.06 | ≥4.6 | ≤25 |

| AP-Ni80Mo12Fe | 80 | 11.7 | 0.9 | Res. | 0.05 | 0.1 | 0.02 | 0.06 | ≥4.6 | ≤25 |

| AP-Ni80Mo15Fe | 80 | 15 | 0.9 | Res. | 0.05 | 0.1 | 0.02 | 0.06 | ≥4.6 | ≤25 |

Self-fluxing nickel alloys Ni-B-Si and Ni-Cr-B-Si-C.

These materials are used for deposition and sintering of coatings resistant to corrosion, friction wear and abrasive particles. The coatings resist gas corrosion up to temperatures as high as 700 - 850 °C, and are resistant to fresh-and saltwater, saline solutions, oil-containing environments, ammonia and in other aggressive environments. They are not resistant, or weakly resistant, in inorganic acid solutions. The alloys melt in a range of temperatures typical of materials with eutetics in their structure. The base structural phase of coatings made from these alloys: Y - hard nickel-based super-saturated solution, chromium carbides of the type Cr23C6 and chromium carboborides; in powders with increased hydrogen content, particles of the stronger carbide Cr7C3 are also present. The coatings' hardness and wear-resistance increases as the content of chromium, boron, silicon and carbon. Boron and silicon form low-melting eutectics with nickel, with a melting point of 950-1080 °C, and restores oxide films on the surfaces of substrata with the formation of borosilicate slags (self-fluxing) in the presence of a liquid phase, and improve the substratum's wetability with liquid metals.

The adhesion, cohesion and wear-resistance of surfaces made from alloys with the same composition under dry friction and abrasive actions increases, as a rule, with higher density (reduced porosity) of the coating. Porosity of unsintered plasma coatings made from self-fluxing alloys can reach 10-12%, and that of gas-sprayed coatings can reach 20%. Reduction of the porosity of coatings and, as a result, a 5-10 times increase in strength is acheived by sintering the coating, which is done either simultaneously with annealment with plasma welding (the PTA process) or with the layer-by-layer deposition of a coating using gas-powder welding by alternating the process of layer deposition with layer fusion. Fusing sprayed layers is also done with a gas-fired burner, a plasmotron flame, through heating in a furnace, or with high-frequency currents. Thanks to their high density (with porosity generally less than 1%), detonation coatings do not require fusion following spraying. Porosity's impact on the quality and workability of coatings is complex. In conjugated surfaces, under semi-dry friction, the optimal porosity - obtained, for example, through plasma spraying without fusion, can promote low wear in a friction assembly. The pores, by accumulating lubricants, can prevent fretting of conjugated surfaces.

Dilatometric studies of sprayed coatings made from the base alloys NiCr13Si2B1, NiCr15Si3B2, NiCr16Si3B3, NiCr17Si4B4 has shown them to be free of phase transmutations when cooling in the range of temperatures from 960 to 20°C. For this reason, phase transmutations occuring in an iron-carbon system with changes in volume can lead to the danger of surface fracturing in steel and cast-iron substrata during cooling. Therefore, it is recommended to cool products with applied coatings made from self-fluxing alloys at a slow pace. The interval of recommended cooling speeds is, for example, for steel 10 – less than 100 100 °C/s; for steel 45 – less than 35 °C/s; for steel 70 – less than 5 °C/s. The general characteristics of Ni-Cr-B-Si-C also include the tendency to maintain hardness and resistance to abrasive wear following drawing-back with heating to 600 °C. The hardness of alloys at high temperatures (“hot” hardness) - for example, at 650 °C - can reach 50-70% of that measured at room temperature.

The field of application of powders made from nickel alloys includes: wear-resistant coatings on parts for metallurgic, mining and oil-extracting, energy, glass and chemical equipment, stamping and pressing instruments, car, train and boat parts, gas-pumping devices, agricultural technology, etc. The alloys are also used to produce mixtures with other materials for use in coatings: carbides, intermetallic compounds, and others.

Self-fluxing iron-based alloys are represented by the high-carbon alloys AP-Cr4Mn2Si2B4V1, doped with vanadium, chromium and manganese, and the iron-nickel-chromium alloy AP-G14 and the medium-carbon alloys FMI with eutectic composition. Coatings made from high-carbon alloy is marked by increased hardness and high resistance to abrasive wear in an aqueous environment, while eutectic alloys (FMI) boast resistance to friction wear at high slipping speeds.

The self-fluxing lead-nickel bronze Cu-Sn-Ni-B-Si is a material for creating wear-resistant coatings for products made from copper, copper alloys, and steel.

Chemical composition of powders and hardness of coatings

| Powder grade | Nominal chemical composition , % | Coating hardness, HRC Typical values | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Main components | |||||||||

| Ni | Cu | C | Cr | Si | B | Fe | Other | ||

| Nickel-based alloys | |||||||||

| AP-NiCu42Si1B1 | base | 42.5 | 0.2 | - | 0.9 | 1.0 | <3.0 | - | 190-230 HB |

| AP-NiSi2B1 | base | - | <0.15 | - | 2.4 | 1.4 | <1.5 | - | 90-92 HRB |

| AP-NiSi2B2 (PS-22) | base | - | <0.12 | 0.7 | 2.3 | 1.8 | <0.5 | - | 18-23 |

| AP-NiCr13Si2B1 | base | - | 0.3 | 13.0 | 2.4 | 1.5 | <5.0 | - | 26-34 |

| AP-NiCr4Si3B1 | base | - | <0.2 | 3.5 | 3.5 | 1.5 | <3.0 | - | 30-35 |

| AP-NiCr9Si3B2 | base | - | 0.3 | 9.0 | 3.0 | 1.6 | <5.0 | - | 32-38 |

| AP-NiCr15Si3B2 | base | - | 0.47 | 15.0 | 3.1 | 2.0 | <5.0 | Co<0.2 | 38-46 42-48 |

| AP-NiCr13Si4B3 | base | - | 0.6 | 13.0 | 4.0 | 2.8 | 3.2 | - | 45-52 |

| AP-NiCr7Si4B3 | base | - | 0.45 | 7.0 | 3.7 | 2.8 | <5.0 | - | 50-52 |

| AP-NiCr16Si3B3 | base | - | 0.75 | 16.0 | 3.2 | 2.7 | <5.0 | - | 47-52 |

| AP-NiCr16Si3B3-U | base | - | 0.52 | 15.5 | 3.2 | 2.2 | <5.0 | - | 42-48 |

| AP-NiCr8Cu6Si2B3P (PG-AN9) |

base | 6.0 | 0.85 | 8.0 | 2.2 | 2.9 | <5.0 | P 0.6 | 48-57 |

| AP-NiCr25Si3B3 | base | - | 1.2 | 25.0 | 2.7 | 2.5 | <5.0 | Mn 0.2 | 45-51 |

| AP-NiCr7Si4B3Mo2Cu2 | base | 1.8 | 0.45 | 7.0 | 3.8 | 2.8 | <5.0 | Mo 2.2 | 50-55 |

| AP-NiCr16Si4B4Mo3Cu3 | base | 2.7 | 0.5 | 16.0 | 4.0 | 3.8 | 3.5 | Mo 2.7 | 52-58 |

| AP-NiCr17Si4B4 | base | - | 1.0 | 17.0 | 4.1 | 3.6 | <5.0 | - | 55-60 |

| AP-NiCr17Si4B4-U | base | - | 1.0 | 17.0 | 4.2 | 3.6 | <5.0 | - | 56-60, HV200 >595 |

| AP-NiCr17Si4B4-R | base | - | 0.8 | 17.0 | 4.2 | 3.1 | <5.0 | - | 55-62 |

| AP-NiCr18Si5B4 | base | - | 1.2 | 17.5 | 4.6 | 4.2 | <5.0 | - | 60-62 |

| Copper-based alloy | |||||||||

| AP-CuSn8Ni5Si1B1 | 4.8 | base | - | - | 0.8 | 0.6 | <2.0 | Sn 8.0 | 140-160 HRB |

| Iron-based alloy | |||||||||

| AP-FeCr4Mn2Si2B4V1 | - | <0.5 | 1.2 | 3.8 | 2.3 | 3.6 | base | V, Mn |

60-64 |

| AP-G14 | 37 | - | 1.4 | 14 | 2.5 | 2.2 | base | Mo, W | 38-45 |

| AP-FeCr11Mn4SiB (FMI-2) | - | - | 0.8 | 11 | 3 | 2.7 | base | Mn 4 | >40 |

| AP-FeNi19Mn10SiB (FMI-4) | 19 | - | 0.35 | - | 3 | 2.7 | base | Mn 10 | 40-45 |

| AP-FeNi9Mn4SiB (FMI-5) | 9 | - | 0.5 | - | 1.2 | 2.7 | base | Mn 4 | 40-45 |

Self-fluxing alloys are produced by gas-spraying a molten solution. The resulting polydispersed powders are subjected to screening into fractions that are narrow in terms of particle dimensions for use in various technologies for spraying and welding coatings: detonation and supersonic spraying, gas-powder coating welding, gas-fired and plasma spraying, laser and electrospark welding, and plasma and induction welding.

Particle sizes (base fractions)

Base fractions of powders for various coating technologies:

| Method of coating application | Particle size, microns |

|---|---|

| Detonation and high-speed spraying | <40, <63 (20-63) |

| Gas-fired and plasma spraying, gas-powder, laser and electrospark welding | 20-63, <100, 40-100, 45-90, 45-125, <125 |

| Plasma welding/spraying | 63-125, 80-160, 94-280, 140-280 |

| Induction welding | 94-280, 40-630, 100-630, <630, <800 |

Based on the client's needs, we can produce powders with other particle sizes. The minimal dimensions of meshes used to classify powders are: - 40 microns (~400 mesh) and 45 microns (325 mesh). Powders are not screened on meshes of less than 40 microns, since gas-sprayed powders typically contain a small amount of fine particles of less than 15-22 microns.

Sample distribution of particles by size, determined by laser granulometry

| Fraction, microns | Number of particles, % by dimensions, microns | |||||

|---|---|---|---|---|---|---|

| 0.29-11.00 | 11.0-15.56 | 15.56-22.0 | 22.0-37.00 | 37.0-74.00 | 74.0-124.5 | |

| 20-63 (<63) | 0.00 | 1.59 | 7.38 | 43.7 | 45.31 | 2.02 |

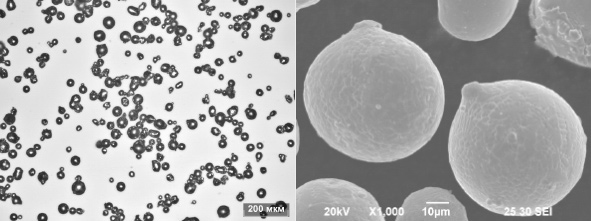

The shape and structure of powder particles

Gas-sprayed powders are primarily spherical in particle shape, with the structure of a cast material

fig. 1

fig. 2

*Fig.1, fig.2: The shape and structure of powder particles in the nickel-based alloy AP-NiCr15Si3B2.

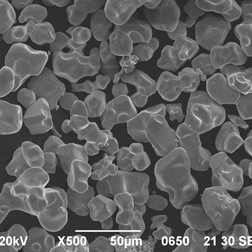

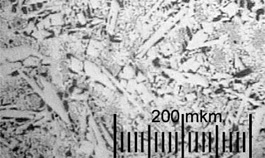

fig. 3

fig. 4

*Fig.3, fig.4: The shape and structure of powder particles in the iron-based alloy AP-FeCr4Mn2Si2B4V1.

Flowing temperature of coatings

Dilatometric analysis of self-fluxing alloys, heat content curves include the following characteristics points: the temperature at which the liquid phase appears, T0, and the temperature at which the maximum change in heat content is observed, Tm, (the peak of flowing on a DTA curve). This range of flowing in self-fluxing alloys, the parameter ΔT = T0 – Tm, plays an important role in selecting the optimal flowing temperature for a coating. It is recommended that the flowing temperature be as close as possible to Tm, at which the coating become more dense (porosity disappears), and a transitional diffusive layer of the necessary thickness is formed and the maximal strength of the coating and substratum is reached. In actuality, nickel alloys of the system Ni-Cr-B-Si-C that contain nickel borides and silicides, as well as chromium borides and carboborides, flow in a wider range of temperatures than ΔT, with gradual assimilation during flowing, during heating (dissolution in nickel) of clusters of high-melting compounds.

Powder characteristics and fields of application

Notes to table:

Tm – melting point (the first peak on the heat content curve of a DTA), reference data;

TS - solidus temperature;

TL - liquidus temperature;

f – friction constant in a friction pair with steel, reference data;

The characteristics of materials and coatings provided in the table are for reference only.

| Alloy grade | Tm °C | Coating properties | Major fields of application |

|---|---|---|---|

| Nickel-based alloys | |||

| AP-NiCu42Si1B1 | 1065 | Resistance to corrosion, shock, friction abrasion; excellend workability. Low friction coefficeint, f = 0.052-0.07 paired with a counterbody of steel 20 | Restoration of dimensions, part welding, filling of cracks and abcesses on parts and frames made from cast iron. Used in the glass industry and other sectors when renovating frames and parts of vehicles |

| AP-NiSi2B1 | 1070 | Heat-resistance, resistance to corrosion, shock and abrasion, good workability | Restoration of dimensions and surface strengthening of cast iron matrices in the glass industry |

| AP-NiSi2B2 | 1060 | Heat resistance, resistance to corrosion, shock and abrasion. Greater hardness than NiSi2B1 and good workability | Restoration of dimensions and surface strengthening of cast iron matrices in the glass industry |

| AP-NiCr13Si2B1 | 1050 | Resistance to shock, high resistance to abrasive and erosive wear, and to oxidation in air up to 850 º, to corrosion in saltwater and in aggressive environments, except for acidic environments. Greater hardness than NiSi2B2. f=0,43 for friction with Cr12Mo steel in open air. Satisfactory workability. | Wear-resistant, extreme-pressure resistant coatings on steel and cast iron. Matrices in the glass industry, equipment at metallurgical factories and the oil & gas industry, and transportation parts |

| AP-NiCr4Si3B1 | 1060 | Resistance to abrasion. Greater hardness but less shock resistance than NiSi2B1. Satisfactory workability | Restoration of dimensions and surface strengthening of cast iron matrices in the glass industry. Matrices and poncheons in the glass industry |

| AP-NiCr9Si3B2 | 1040 | Resistance to shock loads, wear by friction and abrasion, oxidation in air up to 800 ºC, corrosion in aqueous or alkaline environments and other aggressive industrial environments, except for acidic. Satisfactory workability | Wear-resistant, extreme-pressure resistant coatings on steel and cast iron: matrices and puncheons in the glass industry, equipment in the metallurgical and oil & gas industry, parts in pumps, compressors and transport devices. Used as a part of cords with polymer filling |

| AP-NiCr15Si3B2 | 1025 | Hardness in ranges of 38-46 or 42-48 HRC is regulated by an alloy composition based on the client's request. Resistance to shock, high resistence to friction wear, fretting corrosion, cavitational erosion, oxidation in air up to 800 ºC, corrosion in aqueous and alkaline environments and other aggressive industrial environments. Limited cobalt content in the alloy. Good workability with hard alloys. | Wear-resistant, extreme-pressure resistant coatings on steel, cast iron, and stainless steel. Restoration and strengthening of parts of valving in high-pressure cauldrons. The material is accredited by NAKS for use in technical devices at high-risk facilities. Other fields include repair and protection of metallurgical, chemical and oil & gas equipment and parts of vehicles |

| AP-NiCr13Si4B3 | 1030 | Resistance to friction and abrasion wear, shock, corrosion in aqueous and alkaline environments and other aggressive industrial environments. | Wear-resistant coatings for parts in metallurgical and mining equipment, shafts and sealing systems of pumps and vehicles |

| AP-NiCr17Si4B4 | 980 | Medium-alloyed chromium alloy with a lower Tm than NiCr15Si3B2 and NiCr9Si3B2 and improved flowability during flowing. Resistance to friction wear and abrasion, to oxidation in air up to 850 ºC, and to corrosion in aggressive environments | Wear-resistant, extreme-pressure resistant coatings on parts made from steel and cast iron – in particular, on internal cylindrical coatings of shells of inductively welded extruders (HDTVs) |

| AP-NiCr16Si3B3 | 1040 | Resistance to shock, high resistance to abrasive wear, fretting-corrosion, cavitational erosion, oxidation in air up to 800 ºC, corrosion in aqueous and alkaline environments and in other aggressive industrial environments. Workable by cutting and grinding. | Wear-resistant coatings for parts in power engineering machine building (pumps and oil industry valving), metallurgical equipment for hot shops, stamping instruments, extrudors at tire factories, parts for automobiles, vessels and trains - for example, blades of screw-propellors, locomotive parts, car couplings, etc. |

| AP-NiCr16Si3B3-U | 1050 | This material's properties are analogous to AP-NiCr16Si3B3, but it differs in terms of special requirements for particle size (100-280 microns) and the method of controlling for coating properties | Wear-resistant coatings for parts for equpiment in power engineering machine building (pumps, oil industry valving) |

| AP-NiCr8Cu6Si2B3P (PG-AN9) |

950 | In terms of hardness, the material is close to NiCr16Si3B3. Relatively lower flowing temperature and a low friction coefficient when paired with the alumninum alloy ACM (Al-Sb-Mg) and anti-friction bronze of the type Cu-Sn-Pb. | Ring-shaped crankshafts of marine diesels and automobile parts. The composite powder CP-Al5-Ni is used as a substratum. Wear-resistant coatings for cast-iron parts |

| AP-NiCr25Si3B3 | 1050 | A self-fluxing alloy with increased chromium content. Resistance to mechanical wear and gas erosion at increased temperature and under dynamic loads. | Restorating and protection of exhaust valves and the saddles of locomotive diesels, and valvings |

| AP-NiCr7Si4B3Mo2Cu2 | 1000 | Resistance to mechanical wear and shock and increased resistance to corrosion. | Wear-resistant coatings for parts operating under high loads and high temperatures |

| AP-NiCr16Si4B4Mo3Cu3 | 1010 | High resistance to abrasion and friction wear, cavitation and fretting-corrosion. | Resoration and strengthening of transport mechanisms (rolls, bearings) of metallurgical equipment for hot shops, valves and cranks of diesels, pump shafts, plungers of oil drowned pumps, steam valves, blades, knives and screw conveyors of mixers and press moulds in the manufacture of refractory products (ceramics), etc. |

| AP-NiCr17Si4B4 | 1025 | High resistance to abrasion and erosion due to its high-strength Cr7 C3 phase, and to corrosion in fresh- and salt-water, saline solutions, oil-containing environments; resistance to oxidation in air up to 700-750 ºC. f=0.4 for friction with Cr12Mo steel in open air. | Strenghtening surfaces for machines and equipment parts for hot shops at metallurgical factories, oil drowned pumps and sludge pumps, gas-pumping devices, mining, transport and agricultural technology. Strengthening conveyor screws of extruders of polymer materials, etc. |

| AP-NiCr17Si4B4-U | 1025 | The material's properties are analogous to AP-NiCr17Si4B4. Base fraction is 45-125 microns, >125 less than 3%, <45 less than 3%. Hardness of the deposited coating is 56-61 HRC, microhardness of the sprayed and flowed coating is >595 HV 200. | Depositing coatings by spraying, with subsequent flowing. Oil and gas mechanical engineering, strengthening plungers of drowned pumps |

| AP-NiCr17Si4B4-R | 1025 | This material differs from base AP-NiCr17Si4B4 in terms of its improved flowability on the surface of steel parts during flowing - for example, its ability to flow onto lateral facings of parts without forming a bulge. | Strengthening coatings for parts of machine and equipment in power engineering, mining, transport and agricultural technology |

| AP-NiCr18Si5B4 | 1000 | Increased resistance to abrasion | Protection of equipment and machine parts from intense mechanical wear and corrosion |

| Copper-based alloys | |||

| AP-CuSn8Ni5Si1B1 | TS 780 TL 980 | Wear-resistant material with a high friction ration of f= 0.1 – 0.07. The cohesive resistance with latten of coatings flowed with latten at 990-1000 ºC is 160-170 Mpa. | Wear-resistant functional coatings on parts made from copper alloys, steel and cast iron (for example, synchronizer rings on a gear) |

| Iron-based alloys | |||

| AP-FeCr4Mn2Si2B4V1 | 1200 | High resistance to abrasive and hydro-abrasive wear. The alloy forms dense, hard coatings through gas-powder and plasma deposition | Protection of equipment and parts of dredgers, mining, transport and agricultural equipment from abrasive and hydro-abrasive wear |

| AP-G14 | 1100 | A new self-fluxing alloy based on an iron-nickel hard solution with good flowability during flowing. Forms dense, shock-resistant coverings with satisfactory workability. | Wear-resistant coatings of intermediate hardness, for steel and cast iron in metallurgy and the oil & gas industry, power engineering and transportation |

| AP-FeCr11Mn4SiB (FMI-2) |

1130 -1150 | Eutectic alloys are resistant to abrasive, oil-abrasive wear, corrosive-mechanical damage, cavitation and gas erosion. The coatings boast increased plasticity and can be worked by turning. | For example, FMI-2, FMI-5 combined with nickel-alloyed powdered steel AP-FeNi4Cu2Mo is used for welding collar areas of axles, and FMI-4-primarily for welding depositions onto cast-iron products. Restoration of parts in machines and equipment used in the oil & gas industry, transportation, agricultural and transport technology |

| AP-FeNi19Mn10SiB (FMI-4) |

|||

| AP-FeNi9Mn4SiB (FMI-5) |

|||

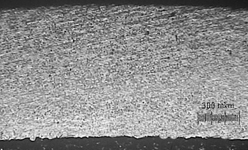

Sample coating structures

fig. 5

fig. 6

*Fig.5: Fused coating made from the alloy AP-FeCr4Mn2Si2B4V1 a steel substratum (etching treatment). Coating hardness 63 HRC

*Fig.6: A fragment of a cylindrical detail – a plunger of a drowned oil pump. Fused coating made from the alloy AP-NiCr17Si4B4-U (etching treatment) Coating hardness 58 HRC

Guaranteed chemical composition of AP-SnSb11Cu6 (Babbit B83) powder, % (mass)

| Grade | Sn | Sb | Cu | Fe | Pb |

|---|---|---|---|---|---|

| maximum | |||||

| AP-SnSb11Cu6 (Babbit B83) |

base | 10.0-12.0 | 5.5-6.5 | 0.1 | 0.5 |

| The powder can be delivered on the client's request with additional control over the admixtures: As, Zn, Bi, Al. | |||||

Guaranteed chemical composition of AP-SnSb11Cu6 (Babbit B83) powder, % (mass)

| Grade | Sn | Pb | Sb | Cu | Bi | As | Fe | Ni | S | Zn | Al |

|---|---|---|---|---|---|---|---|---|---|---|---|

| maximum | |||||||||||

| AP-Sn61Pb | 59-61* | remainder | 0.10 | 0.05 | 0.2 | 0.02 | 0.02 | 0.02 | 0.02 | 0.002 | 0.002 |

| *Powder can be produced with other limits in terms of Sn content, based on specifications. | |||||||||||

Brades and chemical composition

| Grades | Ti | Admixtures, mass %, maximum | |||||

|---|---|---|---|---|---|---|---|

| N | C | H | Fe+Ni | Si | Cl | ||

| RP-Ti grade K-1 | base | 0.07 | 0.05 | 0.35 | 0.35 | 0.10 | 0.003 |

| RP-Ti grade K-2 | base | 0.20 | 0.05 | 0.35 | 0.35 | 1.00 | 0.003 |

| RP-Ti grade S-1 | base | 0.08 | 0.05 | 0.35 | 0.40 | 0.10 | 0.004 |

| RP-Ti grade S-2 | base | 0.20 | 0.05 | 0.35 | 0.40 | 1.00 | 0.004 |

| RP-Ti grade M-1 | base | 0.08 | 0.05 | 0.35 | 0.40 | 0.10 | 0.004 |

| RP-Ti grade M-2 RP-Ti grade M (A)-2 |

base | 0.08 | 0.05 | 0.35 | 0.40 | 0.10 | 0.004 |

| RP-Ti grade OM-1 | base | 0.08 | 0.05 | 0.40 | 0.40 | 0.10 | 0.004 |

| RP-Ti grade OM-2 | base | 0.20 | 0.05 | 0.40 | 0.40 | 0.10 | 0.004 |

Sample chemical composition of RP-Ti grade M-1 powder

| № | Ti | Admixtures, mass % | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| C | O | N | S | Ca | Fe | Ni | Si | Al | Mg | ||

| 1 | base | 0.046 | 0.25 | 0.08 | 0.002 | 0.22 | 0.050 | 0.17 | 0.040 | 0.01 | <0.01 |

| 2 | base | 0.024 | 0.30 | 0.060 | 0.002 | 0.18 | 0.040 | 0.057 | 0.038 | 0.05 | <0.01 |

| 3 | base | 0.045 | 0.28 | 0.050 | 0.003 | 0.30 | 0.030 | 0.040 | 0.032 | <0.02 | <0.02 |

Particle size, packed density and compressibility of powders

| Grades | Granulometric composition, mass %, by fraction, micron | Packed density, g/cm3 * | Compressibility, g/cm3, at a pressure of MPa * | ||||

|---|---|---|---|---|---|---|---|

| +280 | +100 | +45(40) | -45(40) | 200 | 600 | ||

| RP-Ti grade K | ≤ 5.0 | Balance (remainder) | ≤ 10 | 0.89 | 2.70 | 3.50 | |

| RP-Ti grade S | ≤ 1.0 | n/a | ≥ 25 (35) | Balance | 1.15 | 2.60 | 3.24 |

| RP-Ti grade M | 0.0 | ≤ 2.0 | ≥ 15(25) | Balance | 1.02 | 2.44 | 3.35 |

| RP-Ti grade OM | 0.0 | ≤ 1.0 | ≤ 5.0 (5.0) | Balance | 1.36 | 2.72 | 3.48 |

Zink powder AP-Zn

Chemical composition, %

| Grade | Zn | Fe | Cu | Ti | Pb |

|---|---|---|---|---|---|

| AP-Zn Gas-sprayed |

base | 0.1 max | 0.02 max | 0.02 max | 0.02 max |

Powder of Zn-Al alloys AP-ZnAl16

Chemical composition, %

| Grade | Zn | Al | Fe | Cu | Ti | Pb |

|---|---|---|---|---|---|---|

| AP-ZnAl16 Gas-sprayed |

base | 16 | 0.1 max | 0.02 max | 0.02 max | 0.02 max |